Deep hole composite machine tool TFK50

Product Description

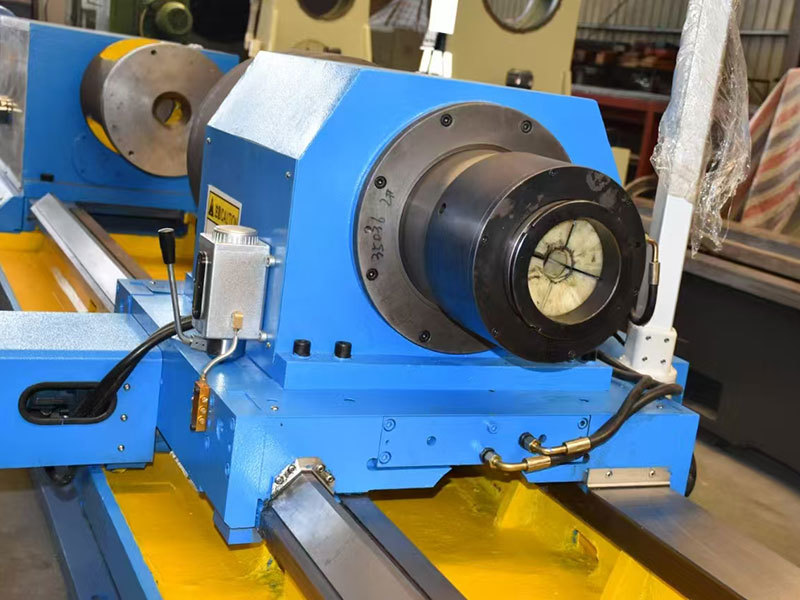

Deep hole composite machine tool is a high efficiency special machine tool developed by Tianrui. The spindle of the machine tool adopts large aperture front cutting spindle to ensure the smooth cutting of iron chips in high speed and fast processing. The machine tool adopts the front and rear double power rotary processing mode, processing materials whether hot rolled pipe or cold pull pipe, can be carried out with high efficiency boring processing. Its processing efficiency is more than 5 times that of the traditional machine tool, is 20 times that of the honing machine, processing precision, roundness size, surface finish can be met, intelligent composite machine tool is the most ideal processing equipment for the production of coal mine cylinder and engineering cylinder.

Machine tool use and product cases

Used for processing coal oil cylinder, small digging oil cylinder, baler oil cylinder, pump oil cylinder and other kinds of oil cylinder processing.

1.The machining accuracy is ≤0.03, and the high finish is Ra≤Ra0.2-0.8;

2.The processing efficiency is more than 5 times that of the traditional machine tools;

3.Using the spindle large aperture front row cutting;

4.The internal hole processing margin of unilateral 10mm;

5.Can be processed cold pull pipe, hot rolling pipe, drilling, sleeve, material, blind hole repair.

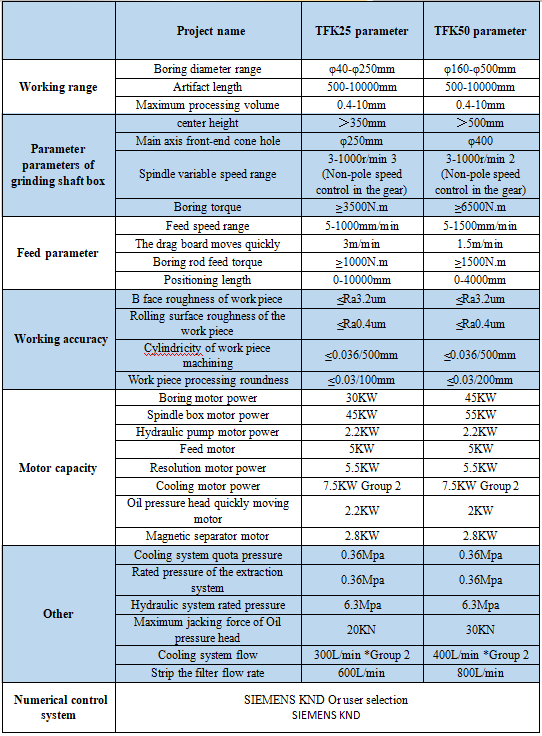

Technical parameter