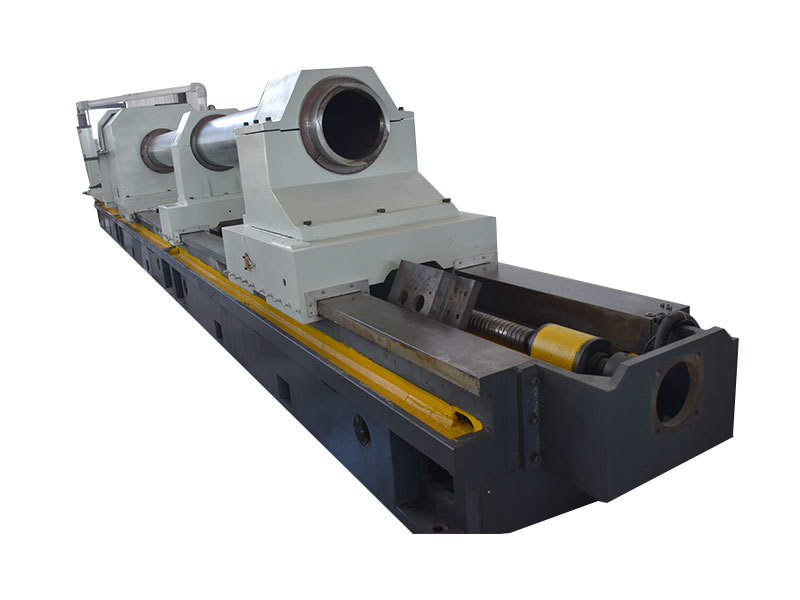

Deep hole CNC scraping and rolling machineTGK 16

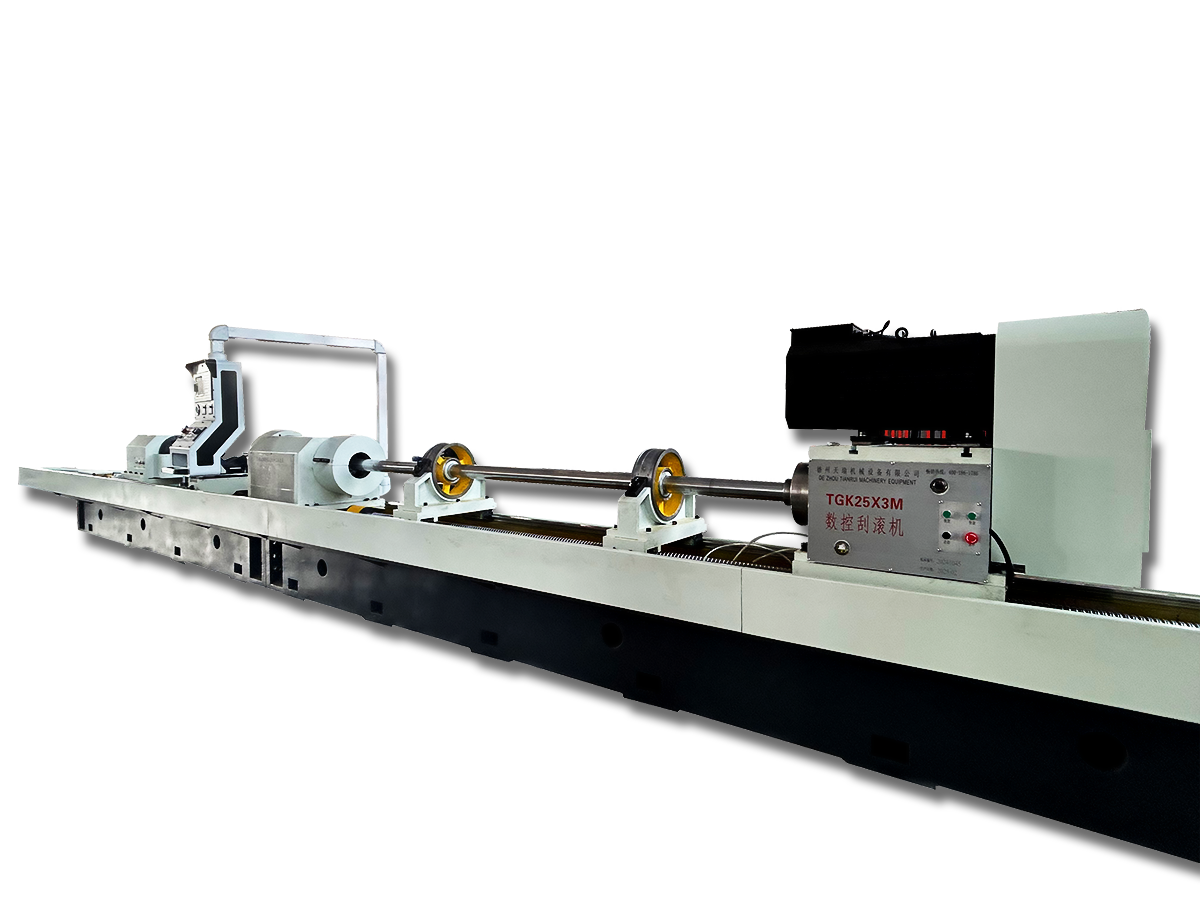

TGK series CNC scraping rolling machine is an efficient deep hole processing machine tool developed by Tianrui on the basis of similar equipment of well-known foreign manufacturers. Its efficiency of processing cold pull pipe (unilateral processing allowance 0.5mm) is more than 5 times that of traditional machine tool, 40 times that of honing machine tool, and it is the most ideal processing equipment for the production of coal mine cylinder.

Machine tool characteristics

1.Machining accuracy of≤0.033, high finish (≤Ra0.2-0.8);

2.The processing efficiency is more than 5 times that of the traditional machine tools;

3.The size accuracy (IT8) adjustment is convenient and accurate, the fine boring tool through the boring head end surface of the screw control of the internal spindle cone surface length to fine-tune the diameter precision;

4.The boring head adopts numerical control program (through the cylinder) automatic control, suitable for mass production;

5. The unilateral margin of the inner hole processing is 0.5mm;内孔加工单边余量 0.5mm;

6. The machine tool can automatically identify the length of the workpiece, without repeated programming according to different lengths of the workpiece;

7.Unique structure, more stable processing.(The actuator fixed tool can be rotated because the guide is more stable).

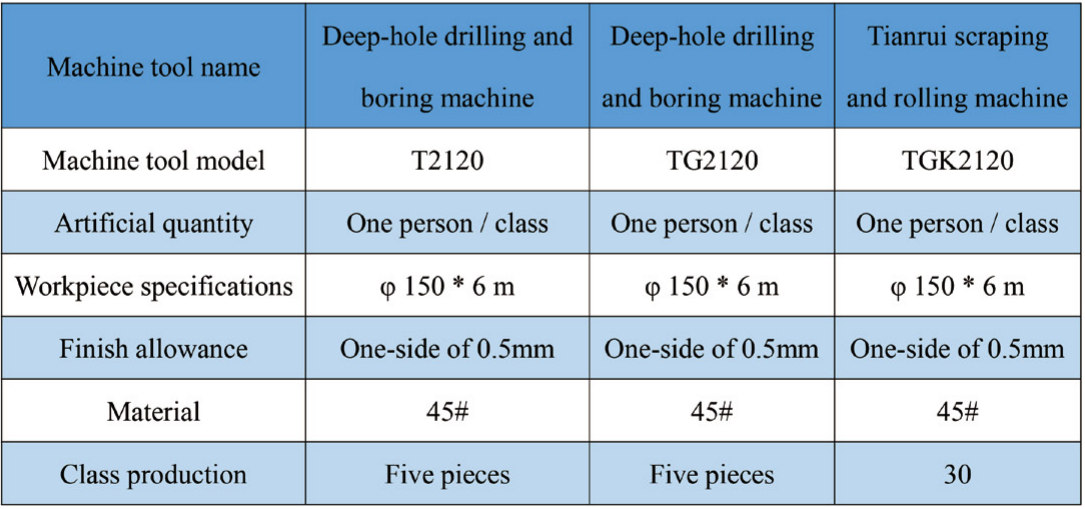

Machine tool processing efficiency comparison

Technical parameters of TGK series scraper