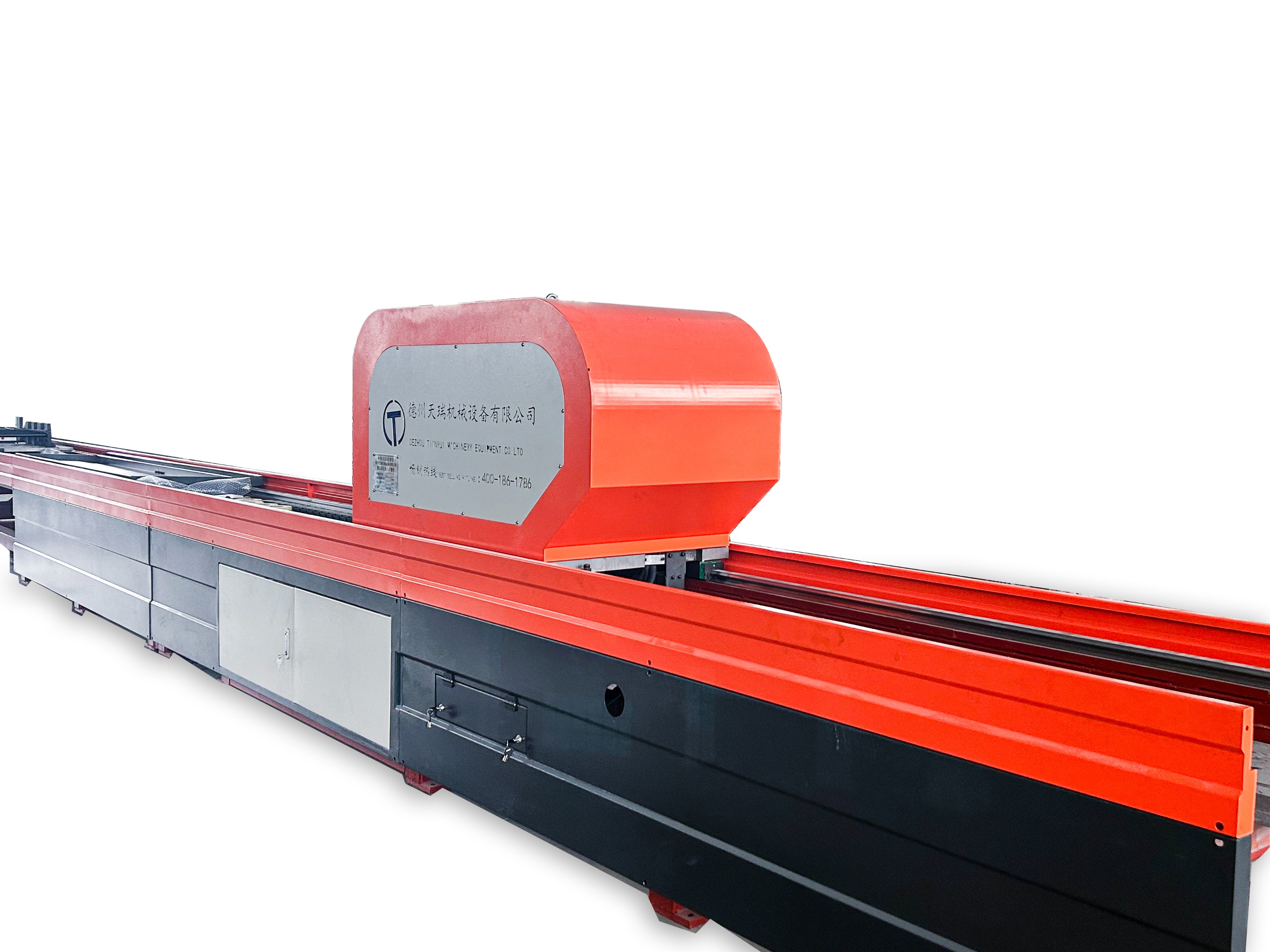

Deep hole honing Machine MK200

Product Description

MK200 MK250 deep hole powerful honing machine is a machine specially used for finishing various cylindrical deep hole parts such as hydraulic oil cylinders and cylinders. The precision of the hole diameter of the parts processed by this machine tool is above IT7, and the surface roughness is Ra0.2-0.4μm. The machine can also perform local honing to correct the taper and ovality of the part.

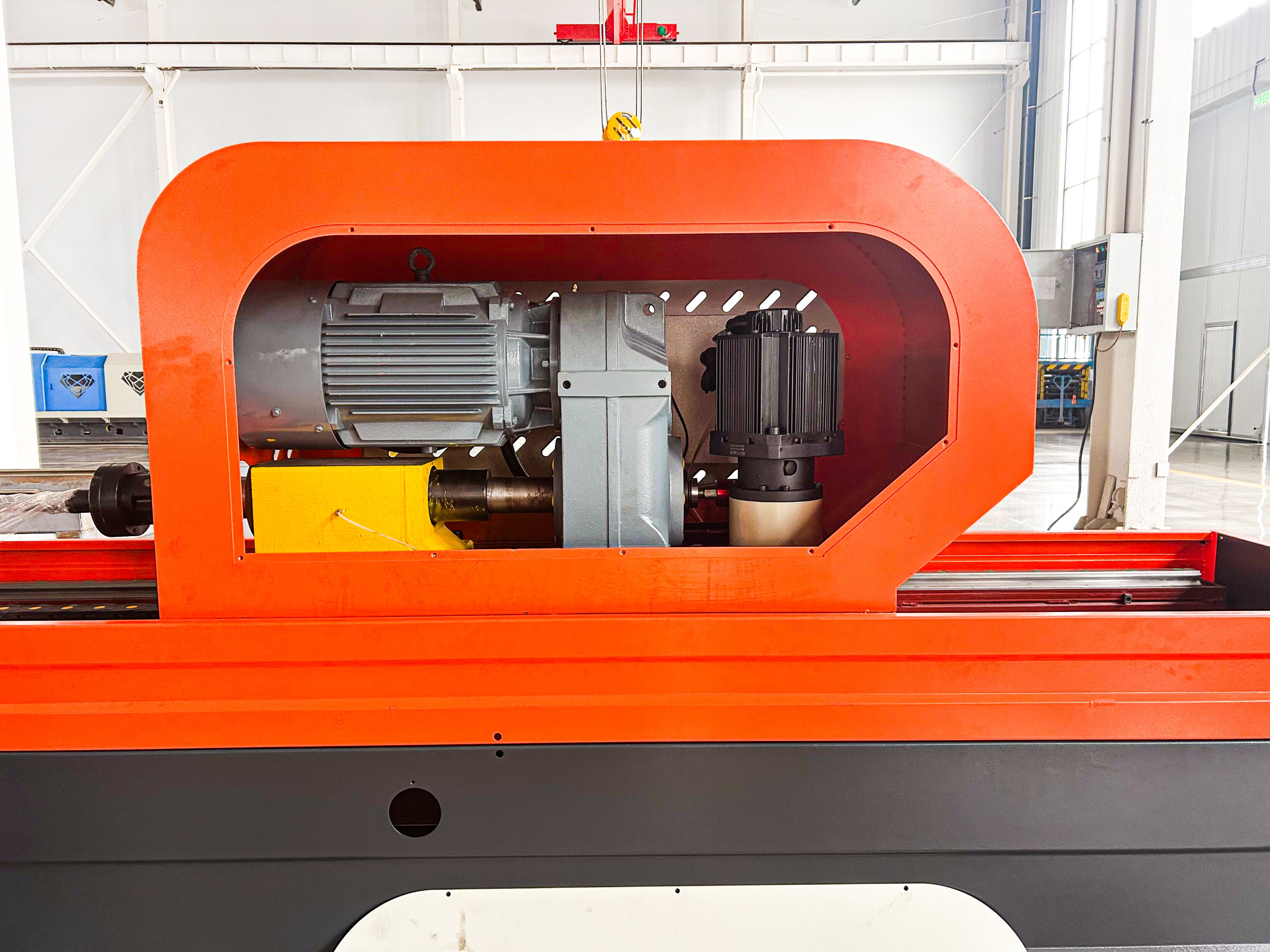

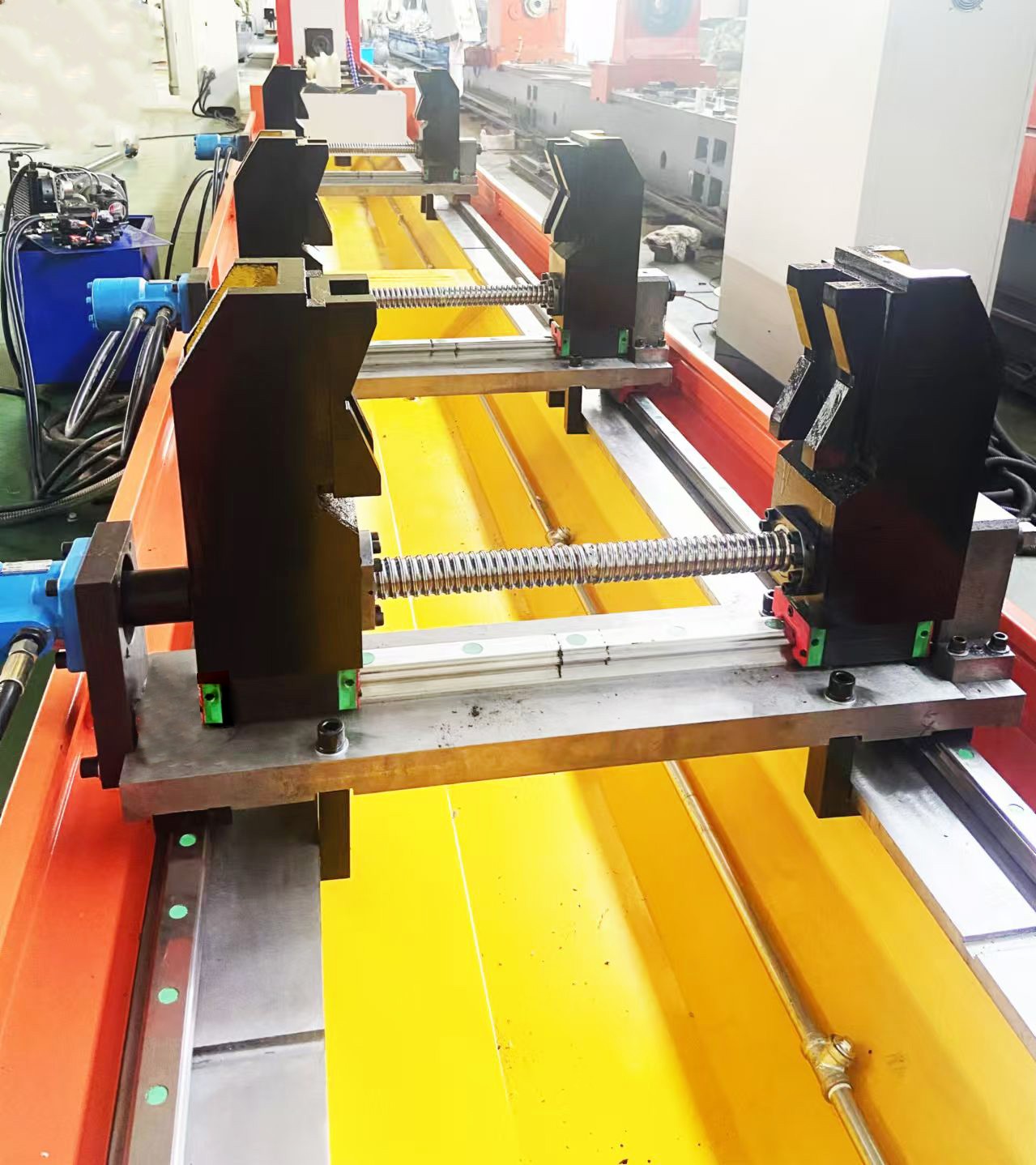

MK200 MK250 deep hole powerful honing machine is equipped with KND numerical control system, linear rolling guide, AC servo motor, grinding rod adopts stepless speed adjustment, smooth commutation, convenient speed adjustment, easy to ensure the accuracy of aperture size and reduce labor intensity.

MK200 MK250 deep hole powerful honing machine During the honing process, the sand bar and the workpiece always maintain a constant pressure, so that the sand bar is strongly ground to ensure the high efficiency of deep hole processing. For general cylindrical deep hole parts, rough boring is performed. Coarse and fine honing, if cold drawn steel pipe is used, strong honing can be directly performed, which changes the traditional process method of multiple processes for deep hole processing and effectively improves productivity. Honed parts are made of cast iron and various types of steel, including hardened workpieces.

The cooling system of MK200 MK250 deep-hole powerful honing machine tool adopts three-stage filtration, which fully guarantees the cleanliness of the coolant. The control of this machine tool is centralized in the electric operation center, which is easy to operate, safe and reliable.

MK200 MK250 deep-hole powerful honing machine can not only undertake large-scale production, but also meet the needs of single-piece small-batch machining. It is an ideal equipment for deep-hole workpiece finishing.

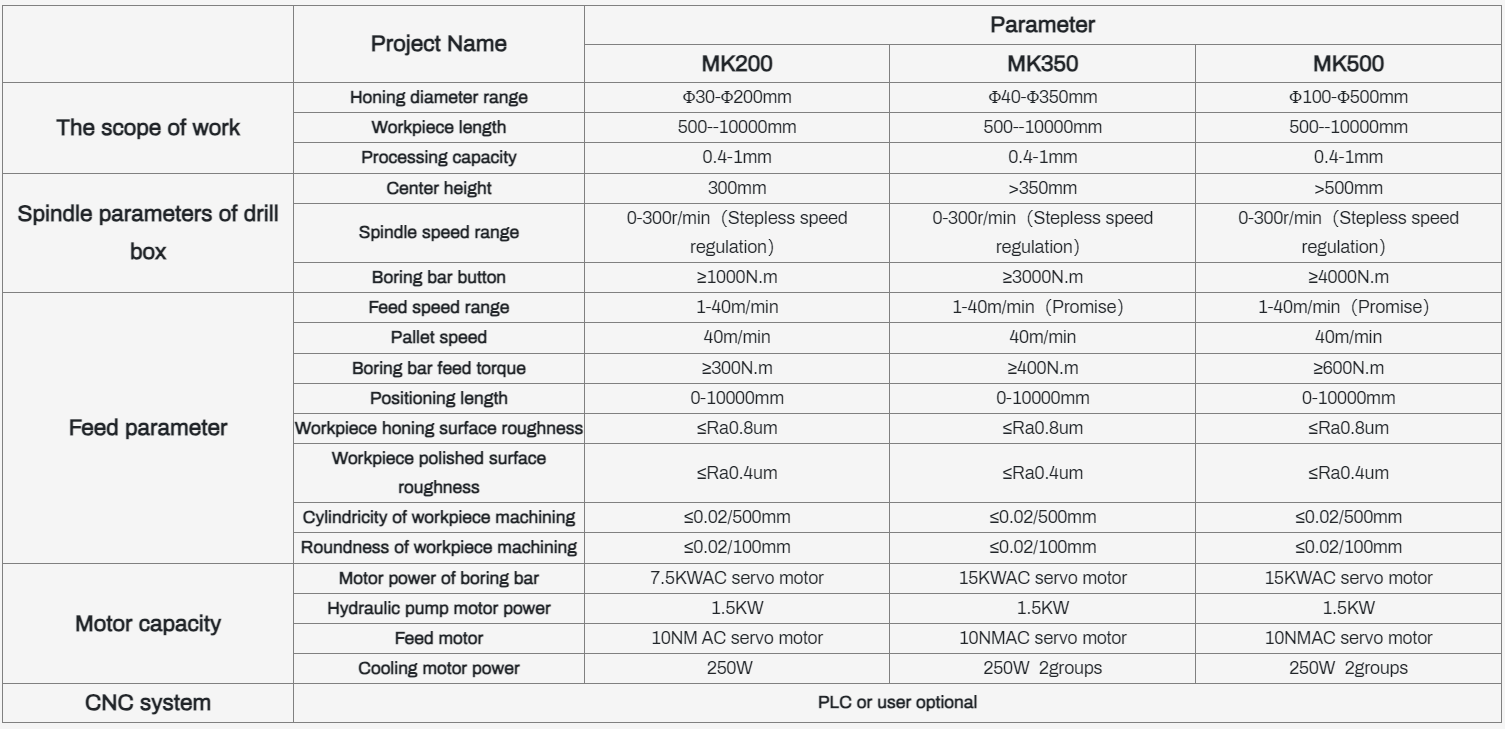

Technical Parameters: