Deep hole honing machine MK 350 / MK 500/MK1000

Product Descriptio

MK series tianrui CNC deep hole honing machine is equipped with numerical control system, linear rolling rail, AC servo motor, grinding rod adopts infinite speed regulation, smooth change, convenient speed regulation, easy to ensure the accuracy of aperture size and reduce labor intensity.

In the process of honing, the sand bar and workpiece always maintain constant pressure, so that the sand bar for strong grinding, to ensure the high efficiency of deep hole processing, for the general cylindrical deep hole parts, after rough boring, if the use of cold pull steel pipe, strong honing can be directly used to change the deep hole processing.

The traditional process of multiple processes effectively improves the productivity. The honing parts are cast iron and all kinds of steel, including hardened workpieces. When the honing diameter is greater than 1000mm, it needs to be customized, which can reduce the center force of the honing head and improve the honing roundness.

Machine tool use and case study

Tianrui CNC deep hole honing machine is suitable for coarse fine honing processing of cylindrical deep hole parts, such as coal cylinder, small digging cylinder, baler cylinder, pump cylinder and other kinds of oil cylinder wall, especially good at processing step oil cylinder.

Machine tool characteristics

1. High machining precision (≤0.02), high finish (≤Ra0.2-0.8).

2. Size accuracy (IT6) adjustment is convenient and accurate, honing head through the cylinder head tight rise open honing (hydraulic or servo).

3. The machine tool through the numerical control program, through the hanging to control the processing size.

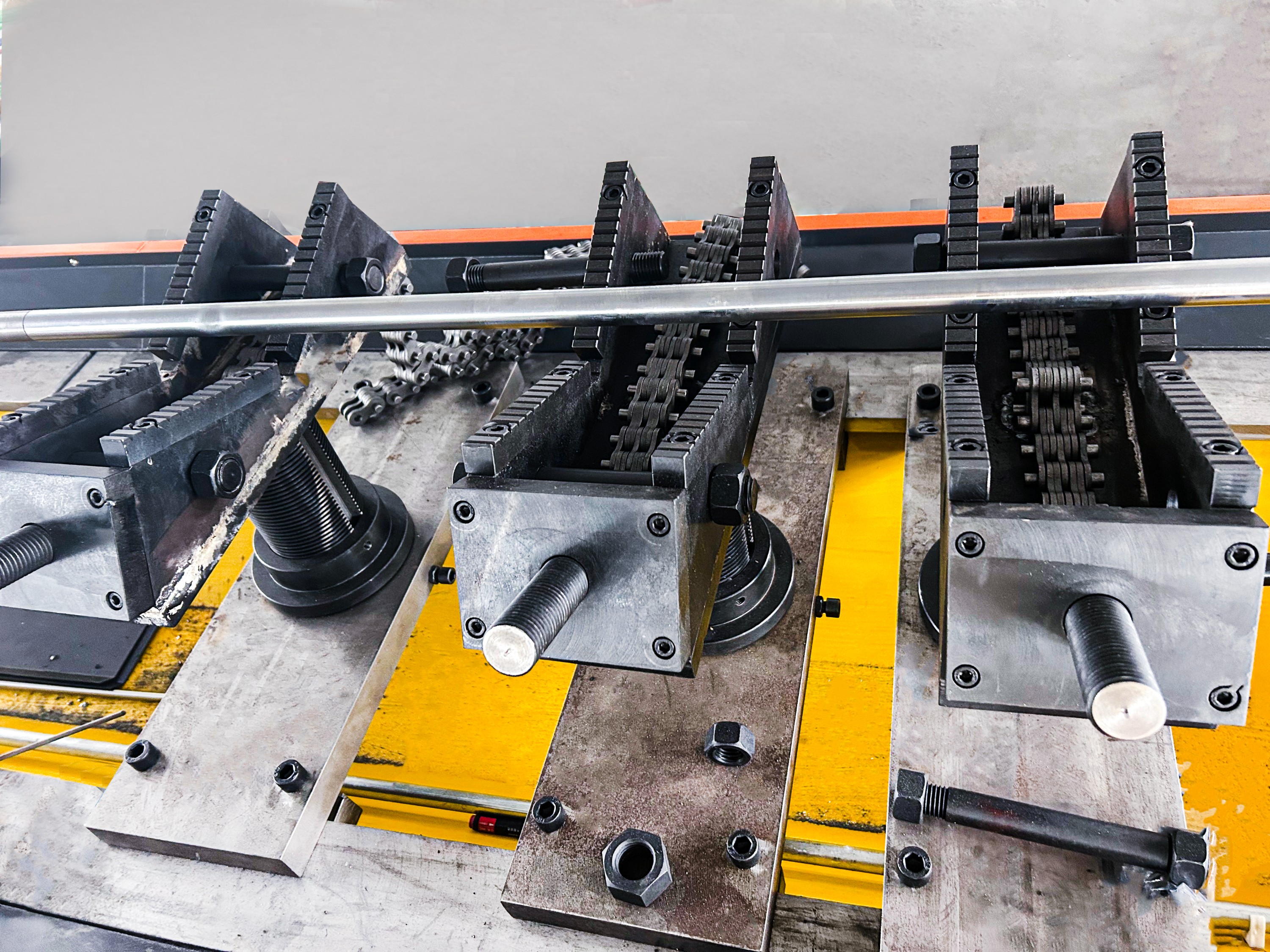

4. Precision oblique rack drive, repeated positioning accuracy of 0.01mm.

5.Assembled heavy duty support, V-type adjustment bracket (customer optional).

6.360 degrees joint joints, free adjustment, easy and convenient (company patent).

7.Large torque input and output power, compared to the peer can improve 2 times the processing efficiency.

8. Simple operation is easy to use, improve the auxiliary time by 2 times.

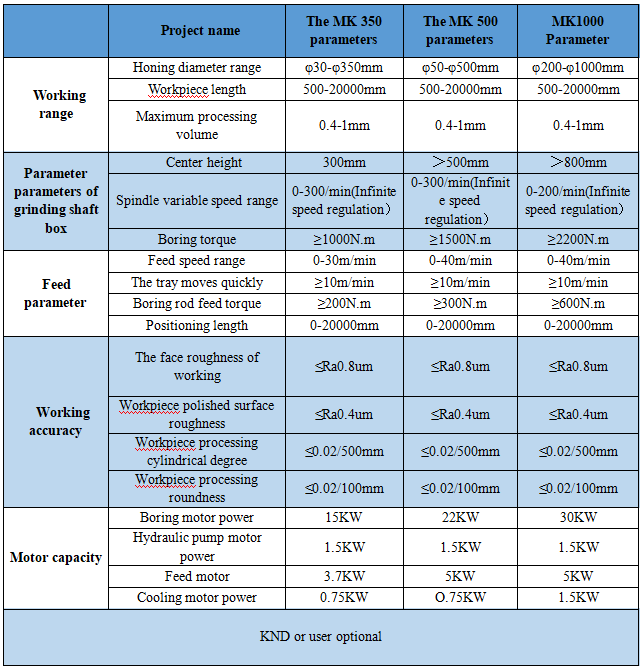

MK350/MK500/MK1000 technical parameter