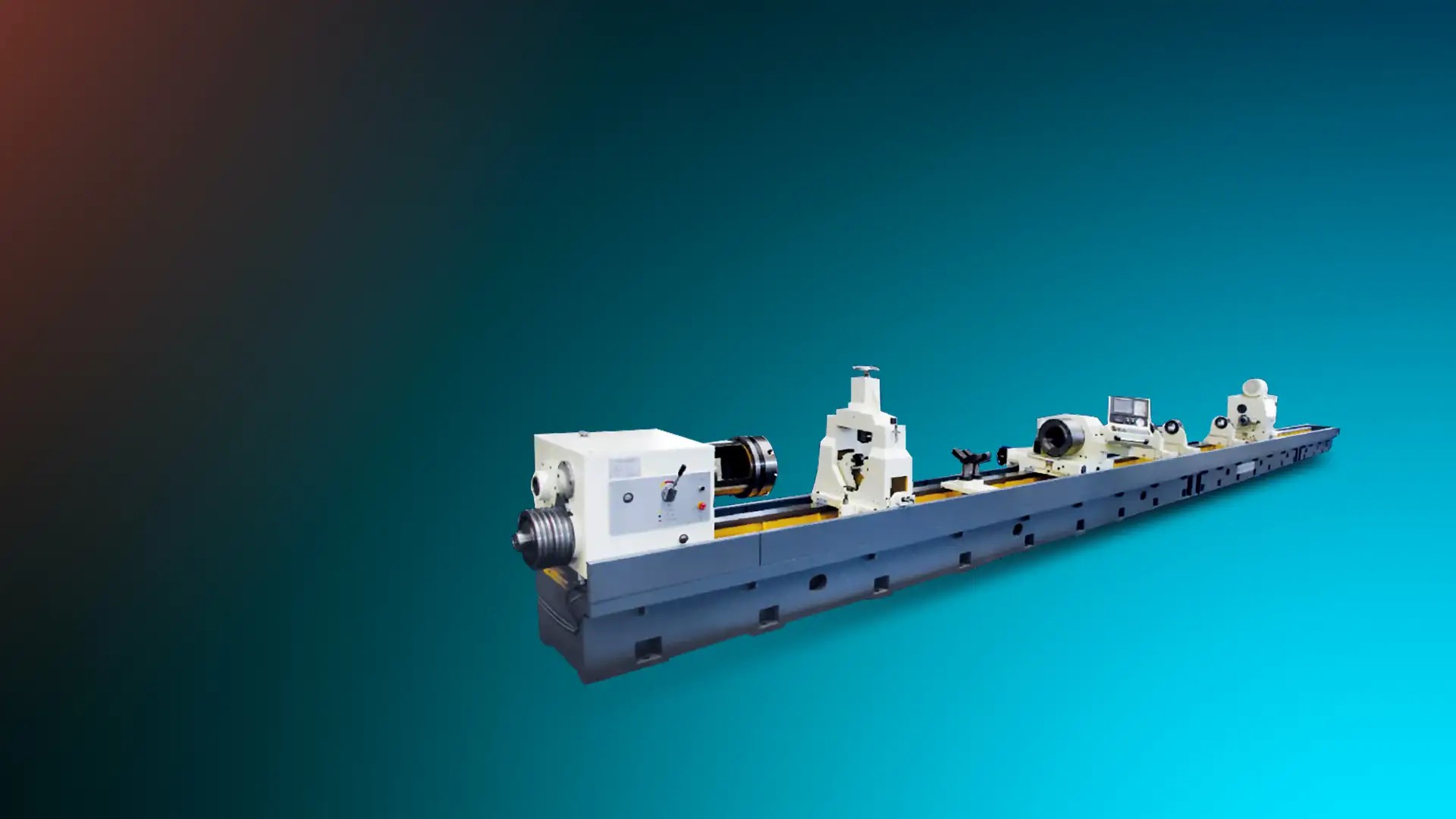

The machine tool is specialized in processing cylindrical deep hole workpiece equipment, such as the spindle of processing machine tool, all kinds of mechanical hydraulic cylinders, cylinder, cylindrical hole blind hole and step hole. The machine tool can not only undertake drilling, boring, but also can be rolling processing, drilling using the internal discharge method.

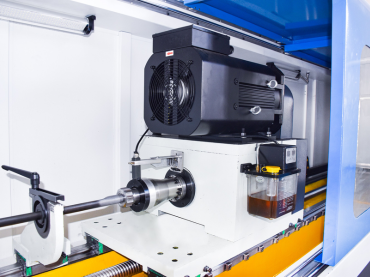

MK series tianrui CNC deep hole honing machine is equipped with numerical control system, linear rolling rail, AC servo motor, grinding rod adopts infinite speed regulation, smooth change, convenient speed regulation, easy to ensure the accuracy of aperture size and reduce labor intensity.

Tianrui Deep Hole Gun Drilling Series leverage BTA technology for single-pass precision drilling. The ZKS2102/ZKS2108 (3-coordinate) features a 360° rotating table for angled/eccentric holes in irregular parts. ZK2102-2/ZK2108-2 (dual-axis) enables simultaneous dual-hole drilling with dual-power operation, ideal for angled center holes. The ZK2103 (single-axis CNC) offers automated cycles for mass production, handling through/blind/step/eccentric/inclined oil holes with tooling. All models excel in end-face drilling.

TGK series CNC scraping rolling machine is an efficient deep hole processing machine tool developed by Tianrui on the basis of similar equipment of well-known foreign manufacturers. Its efficiency of processing cold pull pipe (unilateral processing allowance 0.5mm) is more than 5 times that of traditional machine tool, 40 times that of honing machine tool, and it is the most ideal processing equipment for the production of coal mine cylinder.

Deep hole composite machine tool is an efficient special machine tool developed on the basis of similar equipment introduced by well-known foreign manufacturers.The spindle of the machine tool adopts large aperture front cutting spindle, so as to ensure the smooth cutting of iron chips in high speed and fast processing.